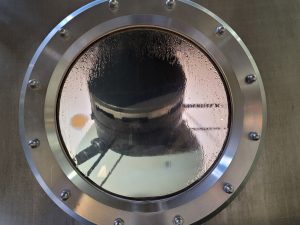

Sanitary sight glasses allow engineers, plant managers, and technicians alike to look inside their equipment without contaminating their systems. Through superior hygienic designs, these types of sight glasses have no crevices or intrusive gaps that could harbor harmful bacteria.

Sanitary sight glasses allow engineers, plant managers, and technicians alike to look inside their equipment without contaminating their systems. Through superior hygienic designs, these types of sight glasses have no crevices or intrusive gaps that could harbor harmful bacteria.

Most applications, especially those in the pharmaceutical industry, require you to meet high standards of sterility. Sanitary sight glasses allow you to meet the regulatory-mandated hygienic requirements of your industry/application, while still being able to monitor your system. This way, you can watch out for:

- System blockage

- Harmful chemical reactions

- Internal corrosion or leakage

- Damaged equipment

- Unbalanced fluid levels

Picking the Right Design

At LJ Star, we know that in order to get the most out of your sanitary sight glass, you must pick the right type of design. This is going to be dependent on your specific application and operating conditions, but there are a number of key differences between the most common types of sanitary sight glasses that you should be aware of. The main types of sanitary sight glasses can be summarized into three categories:

- Threaded sight glasses

- Fused sight glasses

- Clamped sight glasses

Each of these general sight glass designs has their own specifications and abilities that make them better for certain applications. Be aware that this is only concerning the housing of the sight glass and not the actual type of glass itself, which is equally important to consider. We’ll get to that later on in this article.

Threaded Sight Glasses

Threaded sanitary sight glasses use a threaded retainer cap in their design, allowing you to easily remove the sight glass and access/clean the inside of the lens. Without permanently attaching the sight glass to your system, you can always change out components at any point if there is damage to the glass or you’re experiencing operator issues. Having this engineering flexibility makes these types of sight glasses good for applications where there is a higher chance of sight glass corrosion with aggressive chemicals like hydrofluoric acid, concentrated phosphoric acid, or hot concentrated alkali solutions.

Since you will be disassembling or removing parts of the sight glass that come into direct contact with the insides of your system, these designs will naturally allow for more bacterial intrusions. Bacteria also have the potential to find its way into the threads. Not fusing the glass and the surrounding metal can also lead to safety concerns That said, with proper maintenance, you can help to prevent contamination.

Fused Sight Glasses

Fused sanitary sight glasses fuse the design’s viewing glass inside of a steel ring, creating a self-contained unit. The metal frame around the glass provides a rigidity not seen in other designs, which can prevent breakage resulting from uneven bolt tightening during installation.

These types of sight glasses are great for more volatile applications, as they eliminate the chance of a sudden, unexpected rupture of the glass. Sight glass ruptures can be a significant danger in certain applications, leading to lost operator lives and millions in damages. With fused sight glasses, the cracks that could potentially develop will only slightly affect visibility rather than suddenly giving way to catastrophic failure.

Clamped Sight Glasses

By using a hygienic clamping system, clamped sanitary sight glasses allow you to fasten a sight glass to your system without the need for permanent modifications of your equipment. This means significantly faster disassembly and cleaning processes.

Clamped designs are great for applications that need more frequent cleaning or maintenance. Make sure to pick a design that does not warp your equipment when the clamps are put on, as that could interrupt internal flow.

What About the Glass?

Once you figure out what type of sight glass design to use, you also need to pick the right type of glass. Even with the right design, picking the wrong type of glass can have significant consequences. That’s because glasses can break from system hazards such as overpressure, impact, or thermal shock. However, you can mitigate these issues by using the correct glass.

The main types of glass you can use are:

- Annealed soda-lime glass

- Tempered soda-lime glass

- Borosilicate glass

Annealed Soda-Lime Glass

Used in commercial applications like housing windows and drinking glasses, annealed soda-lime glass is sometimes used for sight glass applications. While this type of glass is cheap and easy to get, it’s also easy to break. If you go with this type of glass, expect your design to be susceptible to thermal shock, have poor chemical resistance, only be able to operate under a strict range of temperatures. For most engineering applications, consider a different type of glass.

Tempered Soda-Lime Glass

When thermally tempered, soda-lime glass can have up to 10,000 psi of compressive stress at its surface. This makes it about twice as strong as ordinary annealed glass, meaning it’s more resistant to thermal shock. Tempered soda-lime glass will consistently perform better than its annealed counterpart, and should be used over it in most cases.

Borosilicate Glass

If you’re looking for something even more resistant to thermal shock, borosilicate glass is a great option. With a lower coefficient of thermal expansion than either regular or tempered soda-lime glass, this type of glass is commonly used for sight glass applications that are subject to thermal shock or chemical attack. Borosilicate glass is great for pharmaceutical applications since it meets USP Type 1 standards for parenteral products.