Webcast: The Top Three Steps to Ensuring Sight Glass Safety

Posted by LJ StarKeeping an Eye on Sight Glass Safety

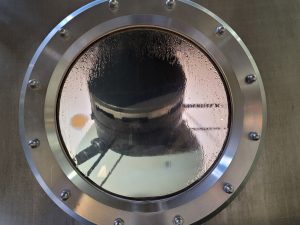

If improperly specified, installed or maintained, sight glasses can be the weakest link in a processing system because they can limit observation capabilities, require frequent maintenance or replacement, or make it difficult to illuminate the vessel in which they’re installed.

Additionally, sight glasses can fail, endangering workers and causing extensive destruction and system downtime. When glass fails under pressure, it is sudden and catastrophic. Glass can fracture at 5 miles per second which can cause irreputable damage to both your workers and your facility.

In systems made primarily of metal, such as pressure vessels or process piping runs, the weak spots are generally sealing joints and glass. Typically, failure of an industrial sight glass on a piece of equipment, or within a piping system, will halt the entire manufacturing process and force downtime until the equipment can be repaired or replaced.

In this webcast, How To Ensure Sight Glass Safety, you’ll learn how to choose the right sight glass for the application and applicable standards, how to install the sight glass correctly and how to routinely and carefully maintain sight glasses.