Sanitary fittings – also called hygienic fittings – can keep your systems locked down and clean while providing a quick disconnect for faster disassembly and maintenance. However, sanitary fittings and system connections must be properly installed and maintained in order to keep your systems clean, efficient and safe.

Sanitary fittings – also called hygienic fittings – can keep your systems locked down and clean while providing a quick disconnect for faster disassembly and maintenance. However, sanitary fittings and system connections must be properly installed and maintained in order to keep your systems clean, efficient and safe.

Here at LJ Star, we know how important it is to make reliable sanitary clamp connections. This is especially true in pharmaceutical, biotech and food/bev applications, where a reliable and leak-free connection is imperative to meet the strict government regulations for sterile process control.

Making sure that your sanitary fittings are connected properly is about more than just getting the right clamp. To ensure proper connections, the fittings need to be installed right the first time they’re set up, and then again after every time your system is disassembled or goes through maintenance. This means that your technicians and plant operators must be trained, and regularly re-trained, on how to use and install sanitary clamps correctly.

If your sanitary fittings aren’t properly installed, you could end up with any of the following:

- Loose connections

- Warped process lines

- Shelves or pockets that can harbor bacteria

- Leakage

If any of these things happen, then you’re putting the hygienic integrity of your process at risk. That’s because process media or cleaning solutions can be trapped or escape through an improperly secured connection.

The problem with this is two-fold. If even a tiny drop of product inside of your system gets out, you could be contaminating whatever’s around it. If something can get out of your system, that of course means that something can also get in it. Polluted air or bacteria could have found its way inside, completely ruining the whole batch of whatever you’re running.

White Paper

Sanitary Clamp Best Practices

The Importance of Clean and Safe Process Clamp Connections

Clamping Consistency

While sanitary fittings are great for secure, hygienic connections, issues can quickly arise when the same clamp is used in different environments. Poorly engineered clamp designs are not predictable, often leading to uneven gasket compression. If you’re working with multiple plants or facilities that use different clamp types, you’re going to naturally have different operating conditions among them. These differences are even harder to manage if those plants are located in different regions around the world.

With different environments come differing pressures and temperatures. Different regions of the world also operate under their own governing regulations and installation procedures, meaning it can be difficult to nail a process down consistently no matter how many installation guides you write.

It’s not uncommon for bigger, globalized companies to have slightly different equipment to handle the same process. Without proper review, some connections can become mismatched, leaving one side of the tube ferrule that meets a specific set of standards, while the other side has a ferrule made to a different set of standards. Any changes in the physical dimensions of your products can influence how effective your sanitary fittings are. With what’s at stake if these clamps fail, you simply can’t risk having a bad connection.

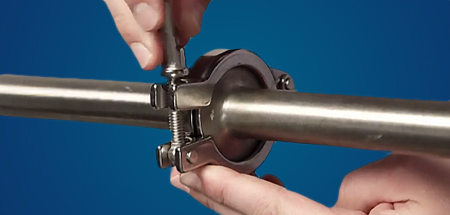

A Better Fit

In situations where ferrules from different manufacturers need to be mated, LJ Star’s clamps and fittings have been designed to provide an efficient, leak-proof connection. The unique “Omega” profile design of our stainless-steel fittings offers high clamping efficiency, reducing the chance of a failed connection. The ferrule, clamp, and gasket connection provide controlled gasket intrusion for your process vessels and systems.

With type 316 stainless steel, these fittings offer superior mechanical properties and chemical resistance compared to fittings made with other materials. This is especially important for pharma, where harsh chemicals and caustic washdowns can quickly degrade other lesser components.

The high quality, precision fit design of these clamps also offers quick access to the process vessel and joint for easy cleaning and inspections, all without sacrificing safety. This means you can have peace of mind knowing that your critical processes stay bacteria– and leak-free, no matter where in the world you are.

Compliant with relevant ISO, DIN, and ASME standards, these clamps were made for hygienic connections. Products include:

- Type “S” Clamp – Single Pin – 304 Stainless Steel

- Type “SH” Clamp – Double Pin – 316 Stainless Steel

- Type “SSH” Clamp – Two Bolt High Pressure – 304 Stainless Steel

- ASME Code Clamps – Redundant Bolting – 316 Stainless Steel

We also offer specialty safety, lockout, and instrument clamps for special applications.

The Future of Sanitary Connections

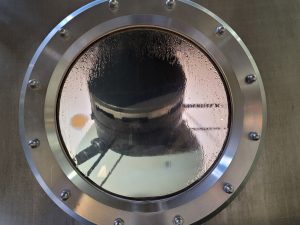

Always one to drive innovation, LJ Star has unveiled a novel new way to combine sanitary connections with process viewing – all in one product. Designed with hygienic processing in mind, the patent-pending Clamp Type Sterile Visual Flow Indicator, or CT-SVFI, offers an innovative new design that prevents o-ring over-compression and the associated contamination issues that are present in conventional threaded or screwed designs.

Instead of using threads or screws, the CT-SVFI secures the sight glass assembly to your process vessel by means of sanitary claps, which apply controlled, uniform gasket compression. Without this controlled compression, typical designs can warp the gasket, trapping bacteria and contaminants. The CT-SVFI mitigates this risk, allowing you to streamline the maintenance and assembly process with fewer cleanings.

To learn more about how the CT-SVFI can aid your hygienic processes, contact us today.