- Home

- Products

- Sight Flow Indicators

- Hygienic Sight Flow Indicators

-

Sterile View Thru Flow Indicator for Hygienic Applications

Sterile View Thru Flow Indicator for Hygienic Applications

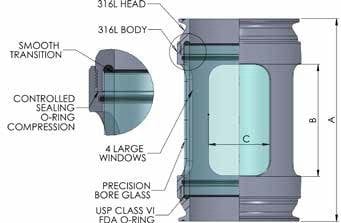

A flow indicator designed to be mounted in-line for high purity applications to provide operators with a clear view of flow of virtually any process pipeline fluid or powder. The sterile-designed flow indicator features an internal-flush style that meets FDA specifications, based on a unique O-ring seal design that minimizes traps where bacteria can buildup. Polished stainless steel connections include sanitary clamp as standard, with butt weld and flange as special order items. Other premium standard features include the use of borosilicate glass, a product contact surface of 220 Grit Electropolish and an housing to help protect the glass from external objects and pipe stress. See our other Flow Indicator products here.

This L.J. Star product carries Canadian Registration Number (CRN) registration.

Request a Quote

Request a Quote

Polished stainless steel sanitary clamp connections are standard.

Standard features include the use of precision bore borosilicate glass, a product contact surface of SF4 (15 Ra Max) Electropolish and a housing to help protect the glass from external objects and pipe stress. Units can be used during SIP/CIP and sterilizing/autoclaving.

Units are available from stock in tube OD sizes from 3/8 to 3 inches with standard lengths shown below. Depending on OD, units are rated to 150 PSIG.

Standard material of construction is 316L Stainless Steel with full material traceability ASME (BPE Standards).

All gaskets meet USP Class VI, are FDA compliant and are fully traceable. EPDM is the standard O-ring material.

| Base P/N | Tube OD | A | B | C | Wt.(lbs) |

| SVF-A03AA1B | 3/8” | 65 | 20 | 9 | 0.3 |

| SVF-A05AA1B | 1/2” | 76 | 20 | 9 | 0.4 |

| SVF-A07AA1B | 3/4” | 87 | 30 | 11 | 0.4 |

| SVF-A10AA1B | 1” | 91 | 30 | 16 | 1.0 |

| SVF-A15AA1B | 1-1/2” | 105 | 32 | 24 | 1.1 |

| SVF-A20AA1B | 2” | 120 | 48 | 35 | 1.5 |

| SVF-A25AA1B | 2-1/2” | 151 | 55 | 40 | 5.9 |

| SVF-A30AA1B | 3” | 175 | 90 | 50 | 7.2 |

| SVF-A40AA1B | 4” | 200 | 110 | 60 | 10.0 |