- Home

- Products

- Sight Flow Indicators

-

Clamp Type Sterile Visual Flow Indicator for Hygienic Applications

Clamp Type Sterile Visual Flow Indicator for Hygienic Applications

The new Clamp Type Sterile Visual Flow Indicator, or CT-SVFI, represents an innovative new approach to hygienic process observation, delivering better hygienic control, lower maintenance costs, and faster, more consistent installation… all from a single device. The patent pending design of the CT-SVFI prevents o-ring compression issues that lead to contamination associated with conventional screwed or threaded designs.

Rather than rely on threads and screws, the CT-SVFI uses sanitary clamps to secure the sight glass assembly. The clamp’s mechanical stop design applies precisely controlled compression to o-rings to eliminate the gasket warping and any o-ring intrusion that can trap bacteria and contaminants. This greatly mitigates the risk of contamination build-up, reducing cleaning issues and frequency.

The engineering-optimized design also offers quick and easy assembly and disassembly that threaded designed visual flow indicators simply can’t match. The clamp connection eliminates the need for additional tools or specialized installation equipment. Polished stainless steel sanitary clamp connections are standard with an orbital weld; Swagelok TS, flange or union connections are available as special order items.

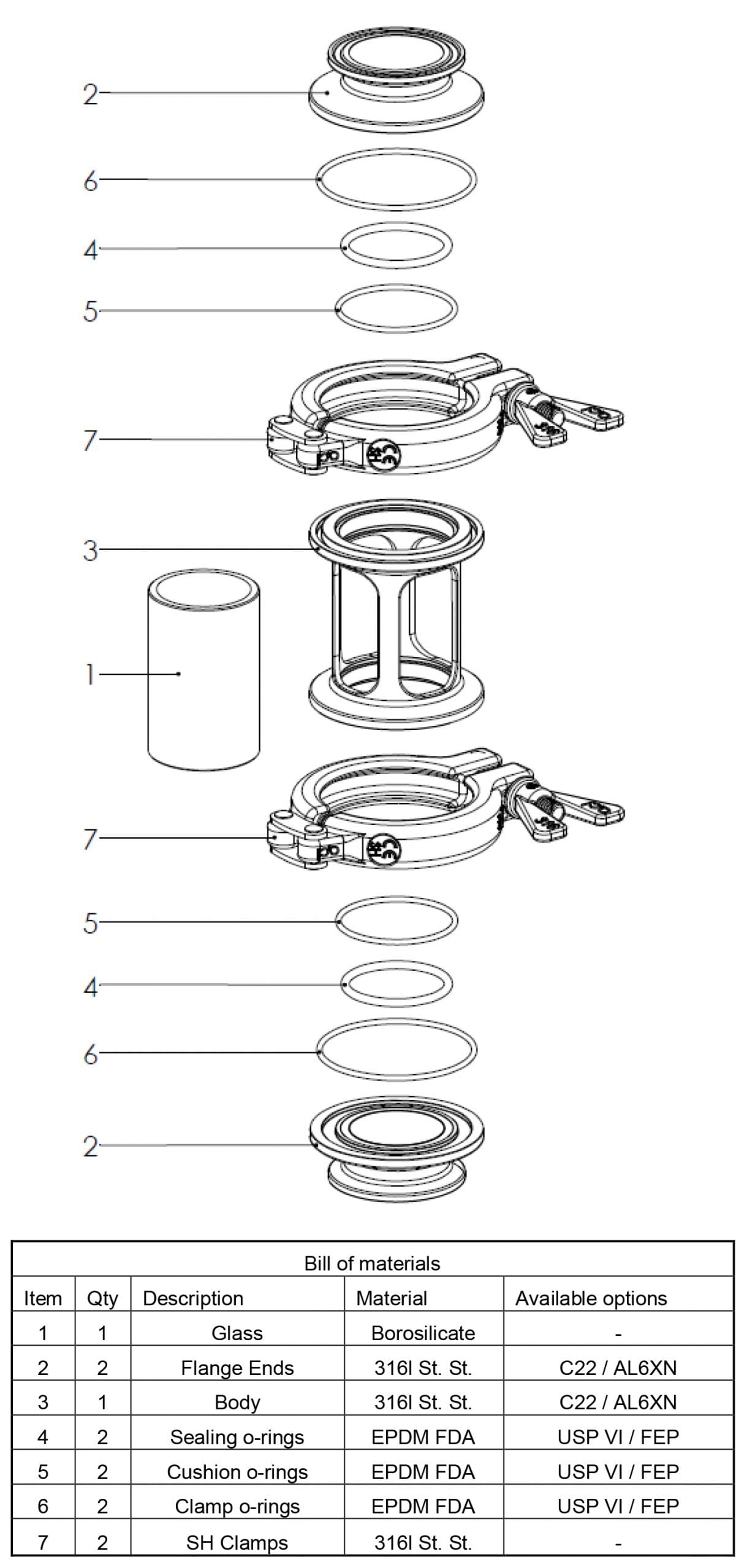

Move your mouse over the image to see how our CT‑SVFI disassembles

The CT-SVFI also offers the largest possible viewing area in its class while still maintaining the structural and mechanical integrity of the component. When compared to typical visual flow indicators, the CT-SVFI allows for a viewing area increase of up to 34%.

The CT-SVFI maintains an EN10204 3.1 certification for steelwork, along with FDA and USP VI certified o-rings, and is fully compliant with the requirements of the European Pressure Equipment Directive 97 / 23 / EC. LJ Star’s CT-SVFI uses SF4 (15Ra Max, EP) 316L stainless steel, with full material traceability ASME. EPDM is the standard o-ring material, with silicone and other options available in tube OD sizes from ½” to 4”.

Request a Quote

Request a QuoteKey Applications

Mounted in-line for high-purity/sanitary/hygienic/sterile applications in the pharmaceutical, food/beverage processing, brewery and biotech industries. Provides a clear view of flow for virtually any process pipeline fluid or powder.

Product Certifications:

- FDA & USP Class VI certified o-rings

- EN10204 3.1 certification for steelwork

- European Pressure Equipment Directive 97/23/EC

- Borosilicate 3.3 viewing cylinder (10:1 FOS)

Product Specifications:

Units are available from stock in tube OD sizes from 1/2 to 4 inches with standard lengths shown below. Depending on OD, units are rated up to 150 PSIG. Custom designed lengths, connection sizes and types are also available.

Standard material of construction is 316L stainless steel with full material traceability ASME (BPE Standards). For corrosive service, Hastelloy® and AL6XN® are also available. All gaskets are USP Class VI and FDA certified and are fully traceable. EPDM is the standard o-ring material with Silicone, Viton®, and FEP jacketed Silicone as options.

| Tube OD | Base P/N | Length A | Window B x C | Width D | No. of Windows | Integral Clamp Size | Pressure PSI | Weight lbs. |

| 1/2″ | SVFCT-A05AA1B | 76 | 24 x 8 | 85 | 4 | DN10/15/20 | 290 | 1.3 |

| 3/4″ | SVFCT-A07AA1B | 87 | 29 x 13 | 102 | 4 | 1″, 1-1/2″ | 253 | 2.0 |

| 1″ | SVFCT-A10AA1B | 90 | 34 x 16 | 102 | 4 | 1″, 1-1/2″ | 123 | 2.2 |

| 1-1/2″ | SVFCT-A15AA1B | 105 | 48 x 26 | 123 | 4 | 2″ | 116 | 2.6 |

| 2″ | SVFCT-A20AA1B | 120 | 55 x 36 | 140 | 4 | 2-1/2″ | 102 | 3.4 |

| 2-1/2″ | SVFCT-A25AA1B | 151 | 72 x 33 | 150 | 6 | 3″ | 94 | 4.2 |

| 3″ | SVFCT-A30AA1B | 175 | 108 x 36 | 165 | 6 | 3-1/2″ | 94 | 5.5 |

| 4″ | SVFCT-A40AA1B | 200 | 135 x 48 | 191 | 6 | 4-1/2″ | 58 | 7.7 |

* All dimensions in mm unless otherwise stated