- Home

- Products

- Gauge Glass

-

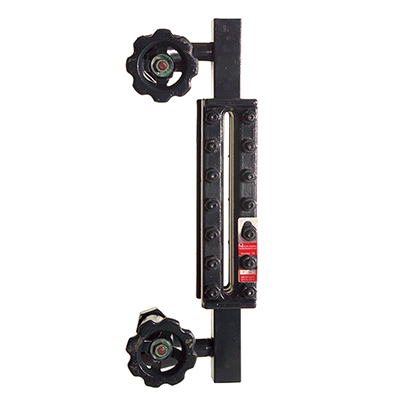

Armored Level Glass Gauges

Armored Level Glass Gauges

Armored Level Gauges are flat glass gauges used where direct visual observation of process fluids is required. These gauges are available in two main types: reflex and transparent. They are suitable for a wide range of applications with pressures up to 6000 PSIG @ 100°F, and temperatures up to 800°F to 2620 PSIG. LJ Star armored level gauges are available in either carbon steel or 316 stainless steel construction materials to meet most specifications for your specific process conditions.

Reflex Level Gauges

For Pressures up to 4000 PSIG @ 100°F

Reflex Gauges use prism glass to provide an excellent indication of the liquid level. All liquids appear black in contrast to the mirror-like surface above. This clean line of separation can be sighted from many yards away.

Available in three pressure-based series, RL, RM and RH, Reflex Level Gauges use glass with molded prisms on the process side designed to absorb light when filled with liquid, and to reflect light where vapor is present, for a clear distinction between liquid and vapor even from a substantial distance.

Reflex Gauges are suitable for use where the liquid is clean, and of low enough viscosity that the prisms will not be fouled. They are less expensive than Transparent Level Gauges and do not require back lighting. They should not be used with liquids that aggressively attack glass, as the glass cannot be shielded. The maximum pressure for use as a water gauge in steam service is 300 PSIG (20. 7 BARG).

Transparent Level Gauges

For Pressures up to 3000 PSIG @100°F

Transparent Gauges use clear, see-through flat glass on both sides, allowing sufficient light so that both the color and the interface of liquids can be viewed. Electric lighted gauge illuminators are available for use on transparent gauges to supplement ambient light. As a result they are ideal for easy viewing of liquid levels in dimly lighted areas. Standard Transparent Level Gauges are designed for -200°F service.

Tubular Gauge Glass Assemblies

Glass-Trac Tubular Glass Gauges use strong clear glass or red line to provide a complete 360° view of the liquid level. Available in any length desired, Glass-Trac Tubular gauges can be fitted with tubular style gauge valves for. Guard rods and plastic tubular protectors are also available for added protection.

See-Level LED Illuminator

The See-Level LED Illuminator for transparent level gauges is certified for Class 1, Division 1, Group B, C & D hazardous locations. Its brilliant green illumination provides long lamp life with low electrical consumption. Rugged in design, the See-Level LED illuminator offers watertight, weather-proof and corrosion resistant performance in the most challenging environments.

It is easily mountable with a NEMA 4x 5 enclosure for added safety.

Steam-Track Steam Gauges

The Steam-Trac steam gauges, in five models supporting pressures as high as 3000 PSI, are made from reflex borosilicate glass with prisms molded into the process side that display black for water and white for steam. Designed with materials that fully comply with ASME requirements, it can be used as a direct reading sight glass as required by ASME Section 1, PG.60. Mid-pressure models include a See-Level illuminator with amber lighting for easy viewing. The high-pressure STB-3000A model, supporting pressures up to 3000 PSI, is used with a red/green filter illuminator.

With multiple sections and a continuous one-piece chamber, Steam-Trac units can be custom built to your specifications. All model units include high temperature coatings, spring washers for consistent torque and quality nickel-plated bolts, nuts and washers.

MAGNE-TRAC™ Level Indicators

Magne-Trac liquid level indicators are easy to install, low maintenance and easy to view. Chambers are constructed of non-magnetic materials, including austenitic stainless steel, alloys or plastics. They are compliant to ASME B31.1 and 31.3. Standard floats are constructed of thin wall, deep drawn 316 stainless steel or titanium. Each float is custom engineered for a specific application or operating process. The unit’s standard indicator consists of anodized aluminum housing, rotating flags and a clear cover. Standard indicators are UV stable with yellow/black flags constructed of high temperature, scratch-resistant, non-corrosive molded nylon.