Why Preventing Sanitary Clamp Galling Is Crucial to Product Purity

Posted on December 14, 2016 by LJ StarWhy Preventing Sanitary Clamp Galling Is Crucial to Product Purity

All makers of pharmaceuticals and biotechnology products have many concerns in common, but none is more critical than maintaining tight control over product purity during manufacturing and packaging. For example, if contamination were to compromise the integrity of a single batch of insulin, it could easily mean a loss of hundreds of thousands or millions of dollars in revenue to the manufacturer. Connecting the complex network of vessels, piping, tubing, valves, pumps, compressors, etc. in a batch process facility demands reliable, long-lasting clamps that provide a consistent level of engagement around the circumference of the connection to prevent leaks.

Quality clamps are essential to maintaining the required joint safety, cleanliness and efficiency in high pressure and high temperature manufacturing processes. However, until recently, many of the clamps used in these settings were susceptible to galling. In this context, galling refers a clamp’s bolt and nut becoming bound or locked together, making it extremely difficult or impossible to open the clamp in order to service the connection.

This post offers some important insights on the causes of clamp galling problems and ways to reduce the potential for product contamination and gain better control over joint maintenance costs.

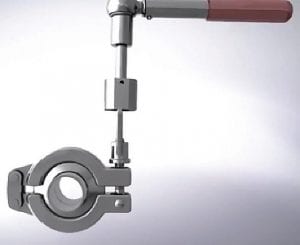

Clamp connections should seal two ferrules together quickly, securely and without creating sites where contamination can collect.

Clamp connections should seal two ferrules together quickly, securely and without creating sites where contamination can collect.

Why stainless steel sanitary clamps gall

A number of factors can contribute to clamp galling in a pharmaceutical or biotechnology plant, including the use of clamps made of the same grade of stainless steel for both the bolt and nut. When over-torqued, either manually or mechanically, these separate pieces of metal can fuse or bind to each other, so they are literally “cold-welded” together. Over-torqued clamps also exert excess pressure on the connection, which can lead to gasket intrusions into the connection, interfering with the flow of process material and allowing particles to collect. Over-torqueing a clamp can even cause pieces of the gasket to shear off and be carried away, contaminating the product.

To avoid overtightening a clamp, always use an approved torque tool.

The cleaning procedures used in pharmaceuticals plants can also play a role in clamp galling. Cleaning a clamp in a parts washer prior to installation can leave behind trace amounts of the sodium hydroxide used in clean-in-place (CIP) solutions. After the solution dries, it can build up in the grooves of threaded parts, contributing to galling by further binding the parts together.

The cleaning procedures used in pharmaceuticals plants can also play a role in clamp galling. Cleaning a clamp in a parts washer prior to installation can leave behind trace amounts of the sodium hydroxide used in clean-in-place (CIP) solutions. After the solution dries, it can build up in the grooves of threaded parts, contributing to galling by further binding the parts together.

Rethinking sanitary clamps

Recently, LJ Star had an opportunity to engage with one of our major pharmaceutical manufacturing customers to explore new ways to prevent clamp galling. Back in 2014, our customer came to us with problems they had been experiencing with our SH Series clamps. Apparently, increasing numbers of galled clamps were requiring “extreme action” to separate components for maintenance. In some cases, galled clamps were forcing maintenance personnel to cut the clamps off their vessels and piping to remove them for servicing equipment.

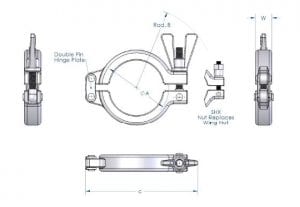

The standard SH Series clamp design.

Our standard SH clamp design is made of 316 grade stainless steel, an austenitic stainless steel alloy that’s widely used in the chemical processing industry. It offers higher performance than the 304 grade stainless steel used in most “commodity” clamps. The SH clamp’s dual-pin hinge, single-bolt design is widely used in pharmaceutical plants because it offers excellent alignment of the clamp halves. Its special “Omega” profile allows for fuller engagement of the clamp around the circumference of the connection for a better and more repeatable 360° compression of the two mating faces without the need to over-torque the nut when closing the clamp.

All stainless steel sanitary clamps are not equal

Working in cooperation with our client we attacked the galling issue by modifying the materials used to create the standard SH clamp. After repeated experiments with how various materials reacted to the client’s part washing process and torquing procedures, we eventually settled on the use of a much harder, galling-resistant Nitronic® 60 stainless steel alloy for the bolt while continuing to use the slightly softer 316 grade stainless steel for the clamp’s wing nut or hex nut.

SH Series clamps with the new anti-galling option are now widely available for use in pharmaceutical and biotechnology operations.

This new approach allows the clamp to withstand over-torqueing; if the nut is damaged, it can be replaced easily and inexpensively. In earlier designs, the nut would have been formed of the harder material and would have stripped the clamp bolt if over-torqued, which would have required scrapping the entire clamp. Today, our client has replaced thousands of standard SH clamps in two of its North American and one European facilities with SH clamps with our new anti-galling option and is enjoying greatly simplified and more cost-effective maintenance as a result.

Because a clamp that’s under pressure that is accidentally disengaged can have catastrophic consequences for both personnel and equipment, we have added the anti-galling option for our Safety Clamp line as well to allow for better clamp performance and safer operation.

Are you current on the industry’s best practices for maintaining clean and safe process clamp connections? Download your free copy of LJ Star’s “Sanitary Fittings Best Practices” white paper to ensure you understand all the steps for correctly installing a clamp connection.

You might also be interested in reading our eBook on How to Eliminate Clamp Galling.

Subscribe to our Blog

Categories

- Certifications

- Company

- In The News

- Industry Information

- METAGLAS® Sight Glasses

- PackExpo 2020

- Sanitary Clamps

- Sanitary Fittings

- Sight Flow Indicator Benefits

- Sight Glass Applications

- Sight Glass Construction

- Sight Glass Lighting

- Sight Glass Lights

- Sight Glass Process Vessel Camera

- Sight Glasses

- Trade Shows

- Webcast