I need a sight glass. What type of glass do you recommend?

Posted on November 14, 2016 by LJ Star A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

Not so fast. There is a wrong way to do anything, and choosing the wrong type of glass for a sight glass can have bad consequences. The glass can break from overpressure, from impact, or from thermal shock—as when a cool wash down hits a sight glass on a hot vessel.

If the contents of the vessel are pressurized and hot, then a jet of boiling liquid or steam and shards of glass at ballistic speeds can injure or kill operators. That’s bad enough, but there is also costly equipment damage, process downtime, scrapped batches, and making a general mess.

A sight glass can fail for a number of reasons, but a primary one is that it was made with the wrong kind of glass for the application.

Annealed Soda-Lime Glass

Some sight glasses are made with (or repaired with) ordinary annealed soda-lime glass, which is the same type of glass used in house windows, drinking glasses and other common applications. It’s cheap and it’s clear, but that’s about it. It’s easy to break. This type of glass is susceptible to thermal shock. It has poor chemical resistance and limited operating temperature. Never use this in a critical application.

Tempered Soda-Lime Glass

Thermally-tempered soda-lime glass is treated to have up to 10,000 psi of compressive stress at its surface. It’s about twice as strong as ordinary (annealed) glass and is more resistant to thermal shock. In fact, most glass baking dishes in the U.S. are made of it. It is often used in sight glasses.

Borosilicate Glass

Borosilicate glass has a lower coefficient of thermal expansion than either regular or tempered soda-lime glass, making it highly resistant to thermal shock. It is used for laboratory glassware, kitchenware (mostly in Europe), and for sight glasses in applications that are subject to thermal shock or chemical attack.

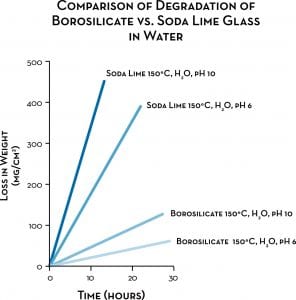

Borosilicate glass also meets USP Type 1 standards for parenteral products, such as injectable drugs. In contrast, soda lime glass has more of a tendency to leach into the process media. After all, glass itself is a chemical compound and will react with media, even water. See our glass comparison.

Materials for extreme conditions

While soda lime and borosilicate glass are the most common types used in sight glasses, sometimes they aren’t suitable. High temperatures are one example: Soda lime glass can be used at temperatures up to about 150 ºC (300 ºF), while tempered borosilicate is good to 280 ºC (536 ºF). At temperatures greater than that, such as in high temperature steam applications, fused quartz or sapphire glass would be a better choice.

Another problem is chemical attack: Some chemicals — for example sodium hydroxide, hot concentrated alkaline solutions, phosphoric acid or fluorine — attack glass. For this service, it is necessary to protect the glass with a mica or Teflon film shield.

Conventional glass discs versus fused glass

The story about which type of glass to use would not be complete without mentioning how the glass is mounted. Glass comes in discs for mounting into sight glass assemblies, or the glass can be fused to a metal frame, a design which makes the glass far stronger because of the compression of the metal ring on the glass.

That’s a big and fascinating topic that I will save for a future blog post.

Subscribe to our Blog

Categories

- Certifications

- Company

- In The News

- Industry Information

- METAGLAS® Sight Glasses

- PackExpo 2020

- Sanitary Clamps

- Sanitary Fittings

- Sight Flow Indicator Benefits

- Sight Glass Applications

- Sight Glass Construction

- Sight Glass Lighting

- Sight Glass Lights

- Sight Glass Process Vessel Camera

- Sight Glasses

- Trade Shows

- Webcast