Increase your ROI on Sight Glass Windows Using These Tips

Materials traceability is becoming an essential business practice to trace and certify sources for all parts and processes. It enables companies to track production, monitor issues, control recalls, or order replacement parts more easily. It helps highlight the importance of material selection at a project’s beginning or during the design phase.

Admittedly, material traceability is easiest when specified at the outset. However, a significant difference is that while traceability can occur after project completion, material selection cannot change once fabrication begins. For example, a lower grade of steel cannot magically transform into 316 Stainless.

Proper material selection can stave off potential problems to help avoid equipment failure and spare capital equipment replacement expenses. And a few timely specifications and decisions during the design phase can improve the return on investment (ROI) for any equipment LJ Star provides, from sight flow indicators to sanitary fittings, hygienic bubble traps, process vessel cameras and observation ports.

Basic ordering specifications for sight glass windows and related equipment

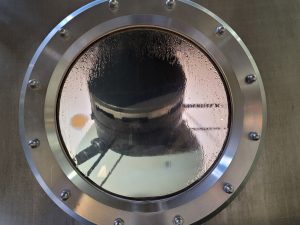

LJ Star has built a reputation for manufacturing quality equipment for process observation, such as sight glasses, sanitary fittings and related equipment. A sight glass window or observation port can benefit many manufacturing processes. It allows operators to monitor the process, check fluid levels, ensure desired chemical reactions occur, and more.

LJ Star has built a reputation for manufacturing quality equipment for process observation, such as sight glasses, sanitary fittings and related equipment. A sight glass window or observation port can benefit many manufacturing processes. It allows operators to monitor the process, check fluid levels, ensure desired chemical reactions occur, and more.

Mounted cameras allow remote monitoring to maintain operator safety and avoid process contamination. Level sensors can help measure and maintain fluid levels, while bubble traps remove air bubbles from fluids to help maintain the desired intrinsic properties.

Many of these components and equipment come into direct product contact and must adhere to stringent sanitation standards. The construction requires durability and reliability to withstand processing temperatures, pressures, chemicals, and general environmental conditions.

For example, when manufacturers order a sight glass observation port, the following play a role in initial specifications:

- Chemicals involved in processing

- Number of batches

- Temperature

- Pressure

- Cleaning and sterilizing cycles

The specifications for other equipment within the system, specifically the piping, tank material, and existing gaskets can be matched to material selection for the observation port and components.

The materials used for the observation ports’ glass portion and the metal clamps and gaskets must withstand the chemicals used in the manufacturing or cleaning processes. Increasing the concentration of caustics used in the cleaning cycle or increasing the frequency of the cycles can degrade the equipment if it is not designed to accommodate those levels.

Some industries can only shorten cycle times with incredible difficulty. However, in an industry such as food and beverage, companies often maximize batch runs to get the most out of each cycle. The faster the company can run a cleaning cycle or change out, the more batches the machinery can run. When shortening a cleaning cycle, achieving the proper hygiene level might mean increasing the temperature, caustic concentrations, or both. This can contribute to material corrosion, mainly when using a lower steel grade.

There is an available blog post about the risk of corrosion related to observation ports and materials used that provides more details: Will My Sight Glass Corrode?

Consider documentation requests early

Companies should also prepare any requests for compliance certificates or documentation in advance. LJ Star offers its customers sophisticated software databases that are completely secure to protect confidentiality and help find some documentation online.

Material that meets ASME standards can be more costly than standard-grade materials of the same type and does not involve a simple substitution. This applies to the European equivalent standards called PED or pressure equipment directive. Customers requiring materials that meet these standards must specify this upfront to avoid delays, recalls and extra expenses.

However, if ASME-grade materials are required for a project, this should be specified upfront to facilitate ordering the proper materials and to ensure the final product meets the standards.

While available software can aid with traceability, it is much more challenging to retrace material pathways once a project is complete or a product is delivered. Most testing requires samples of the material to be taken when it is poured, for example, for each component. This applies to metal and glass selected for the observation port, whether borosilicate, sapphire glass or quartz. Once the components are assembled and installed on the equipment, it complicates obtaining documentation.

All components at LJ Star are constructed according to the appropriate industry standards, such as DIN technical standards developed by the Deutsches Institut fur Normung. This German organization defines industry standards in engineering, manufacturing and technology.

DIN standards provide guidelines, specifications, and procedures for manufacturers to follow to ensure that the products meet certain quality and safety requirements.

Additional processes that impact the material selection and final product performance

Electropolishing offers an effective finishing process that can be applied to components with metal surfaces, such as the sight glass observation port or the entire interior of a tank or vessel. This process, also known as an aftermarket finish, smooths the surface layer of the metal to rid it of imperfections. This removes rough or porous surfaces where bacteria can grow to avoid a potential bioburden. In addition to improving the cleanliness and system sterility, electropolishing also can improve the corrosion resistance and enhance the durability of the observation port.

The payoff of long-term planning when making a material selection

Some companies upgrade material selection to ensure the equipment can withstand a more intense cleaning cycle if the process or product changes. For some companies, a 316 Stainless might represent an upgrade, whereas others might move from a 316 to a duplex to supply the equipment with greater processing and cleaning flexibility.

These companies generally evaluate purchases based on the total cost of ownership (TCO) which yields benefits over the long term. While the high-grade material may cost more upfront, it will supply a longer lifespan and prove to be less of a burden in maintenance over time.

For example, a manufacturer recently requested a quotation comparing observation port equipment constructed of a lower grade of material to that same system made of a higher grade of metal and glass. This company found it was replacing its equipment every six months due to the combination of material quality and the processing conditions it experienced.

The basic system, with a six-month anticipated lifespan, cost $3900, while the equipment upgrade was $21,000, with an expected lifespan of five to fifteen years.

Assuming a constant manufacturing rate, the less expensive materials will cost $7800 per year without other factors affecting production. This doesn’t include calculations for the downtime necessary to pull out and replace the worn equipment. The upgrade cost spread over five years is $4200 per year. Should the upgrade supply a lifespan of ten years in the mid-range of the estimate, the cost per year drops dramatically to $2100 per year.

The return on investment, in this case, is clear, with the upgraded material supplying a higher ROI. The inferior material will require frequent replacement and cost more in the long run.

The customer has the final say in material specifications

In terms of choice, numerous combinations can involve glass types, gasket materials and the clamps and housings involved in the equipment construction.

Borosilicate glass is resistant to high temperatures and most chemicals. It is durable and transparent making it an excellent choice for many manufacturing processes. However, it can be prone to cracking or damage if exposed to certain chemicals or temperatures outside of its specified range.

On the other hand, Sapphire glass is highly durable and resistant to scratches, wear and tear. It is made from high-purity aluminum oxide using a process known as crystal growth. This makes it an excellent choice for operations that involve extreme temperatures and fluids such as slurries or harsh chemicals.

Regardless of the application, the team at LJ Star can work with its customers to accommodate various environmental and processing factors, such as temperature range and chemical exposure.

Multiple gasket options and numerous material combinations are available, making the gasket portion the most difficult to specify.

The metals surrounding the glass can start with carbon steel to Stainless 304 to 316 or higher-grade materials like Duplex stainless steel or Hastelloy.

Material choices narrow as specifications such as temperature or caustics dictate. Open and honest communication aid with proper material specification.

It is difficult for the supplier to recommend materials when most processes are proprietary, and companies are reluctant to provide the details. The burden of responsibility lies with the customer’s engineering staff paying careful attention to the material options and matching the material choices against any future cycle times or frequency changes.

The staff at LJ Star is always available to consult on new projects and help guide material selection based on project specifications. Contact us to discuss your material options today.