LJ Star Sight Flow Indicators for industrial applications are the most common flow indicators style that enables visual observation of process flow through a pair of sight glasses mounted on a carbon steel body.

They are commonly used in industries that require a tool to monitor the speed and quality of liquid, gaseous products, or raw materials such as Chemical, Pharmaceutical, Food and Beverage, Agriculture, Marine and Industrial. With LJ Star Incorporated, you can be assured of high-quality industry-proven products that guarantee long-lasting use at an affordable cost.

What is a Flanged Sight Flow indicator?

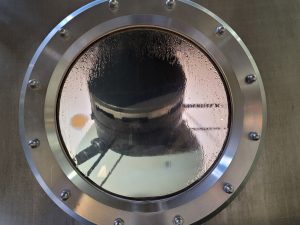

A sight flow indicator is a body with one or more viewing windows, usually with gaskets, and a way to mount the indicator to the pipeline, such as flanged, threaded, or sanitary clamp connection. Flanged industrial sight flow indicators are often used in industrial applications between the API valve and tanker piping, allowing the operator to see fuel flow to or from tank.

What is a Flanged Sight Flow Indicator Used For?

Recommended for monitoring either horizontal or vertical lines with upward flow, the flanged version of our standard view-through flow indicator ranges from 1/2 in. to 12 in. and is full-ANSI rated up to 6″. This is important to consider when working with applications that are associated with hazardous or corrosive materials. The quality investment-cast body is made from stainless or coated carbon steel. It is fitted with independently bolted glass retainers.

How Does a Flanged Sight Flow Indicator Work?

A flanged sight flow indicator works by providing a window to observe the process in a pipeline safely. The operator can clearly see how the process liquid moves through the pipeline and can identify any irregularities that might be present. The flanged mounting option can be specified for various industrial indicator applications.

What Are the Different Types of Flanged Sight Flow Indicators?

There are multiple types of sight flow indicators available to monitor processing systems. Some applications require a full view indicator, while others need an option that can stand up to more rugged processing condition. All of our sight flow indicators are available in a flange mounted design. Choosing the right one depends on the application and its specific processing criteria.

How to Select the Proper Flanged Sight Flow Indicator

There are many considerations for selecting the ideal flanged sight flow indicator. First it’s important to select the right type of indication for your application and from there you can tailor it to the correct flange mount. This online guide walks you through the steps

View Through vs. Full View

A view-through flow indicator has two opposing windows so that an operator can see the intervening flow of fluid lighted from behind. This design is suited for ANSI pressure classes, high temperature, and harsh fluid applications.

360 view is ideal for the observation of process fluid for clarity, color, foam, and other conditions, and for the presence of moisture. Depending on the model it may or may not be suited for high temperatures or pressures.

Type of Indication

Rotary, flapper, flutter, ball, or drip Indicators are available that can help you easily gauge the direction and speed of flow of the process material. Indicators are particularly helpful with colorless gases and opaque fluids.

Carbon Steel vs. Stainless Steel

Carbon steel is generally used for industrial indicator applications. Stainless steel offers better corrosion resistance and is standard for pharmaceutical, food & beverage applications.

Gaskets

This doesn’t really affect the selection, as all sight flow indicators are available with a wide variety of gaskets. Just be sure that the gasket material selected is compatible with your process media and temperature requirements.

Type of Glass

Most of our sight flow indicators are available with windows made of either standard soda lime glass (for temperatures below 300◦ F) or borosilicate glass (for temperatures between 300–500◦ F.)

Borosilicate glass is more resistant to thermal shock and caustic than soda lime glass and should be specified in areas where hot equipment may experience washdowns with cool water or corrosive chemicals.

Quartz or sapphire glass is recommended for temperatures greater than 500◦ F, such as in high-temperature steam applications.

Glass can come as a conventional glass disc or as a glass disc fused to a metal ring during manufacturing. Fused sight glass windows, such as our METAGLAS® and MetaClamp® brands, hold the glass in concentric compression that makes the glass resistant to bending stresses that would otherwise cause cracks or failure. They are preferred when high-pressure ratings, impact resistance, thermal shock resistance, and high safety margins are desired.