Compressed or Fused Sight Glass? Sight Glass Best Practices

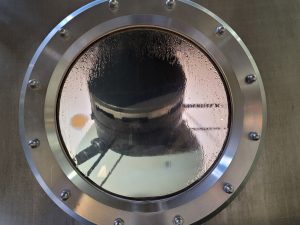

Posted by LJ StarFused sight glass is sometimes used to promote some brands of sight glasses based on the belief that greater fusion of glass to metal during the manufacturing process will produce a stronger finished sight glass for use in chemical and pharmaceutical processes.

During manufacturing, the glass is melted within the metal ring as the ring expands. Then, the temperature is raised to the point where the glass and the metal ring fuse together. When the unit cools, the glass hardens before the metal ring shrinks back to its original size. This places the metal ring in tension and the glass in uniform radial compression. The most compression is produced by using an alloy of metal that shrinks a lot as it cools in combination with a type of glass that shrinks little when it cools: the greater the difference, the greater the compression. Fusion – getting the glass to stick to the metal – is easy to achieve but not as critical to sight glass reliability as compression. Compression strengthens the glass because it is stronger than tensile forces that could create internal torque on the glass. Therefore, it is the level of compression, rather than fusion, that predicts the reliability of a sight glass.

A recent study shows that the combination of glass and metal that provides the most compression also provides the highest strength. The study compared a sight glass made of soda-lime glass and a Duplex stainless steel frame with a borosilicate sight glass (also with a Duplex stainless steel frame) to analyze the amount of radial compression created by the difference between the glass and the metal in a coefficient of thermal expansion as the sight glasses cool. The analysis showed the borosilicate glass produces significantly more compression than one made with soda-lime glass. Also, there is a direct relationship between the amount of compression and the strength of the sight glass. The borosilicate sight glass has far greater pressure capability. Strength is also important for worker safety and because it reduces the need for sight glass maintenance and replacement.

A recent study shows that the combination of glass and metal that provides the most compression also provides the highest strength. The study compared a sight glass made of soda-lime glass and a Duplex stainless steel frame with a borosilicate sight glass (also with a Duplex stainless steel frame) to analyze the amount of radial compression created by the difference between the glass and the metal in a coefficient of thermal expansion as the sight glasses cool. The analysis showed the borosilicate glass produces significantly more compression than one made with soda-lime glass. Also, there is a direct relationship between the amount of compression and the strength of the sight glass. The borosilicate sight glass has far greater pressure capability. Strength is also important for worker safety and because it reduces the need for sight glass maintenance and replacement.

The study also compared the compressive force of a sight glass made with proprietary soda-lime glass coupled with a Hastelloy C22 stainless steel ring (which is touted for its high glass-to-metal fusion) with that of a Duplex/borosilicate sight glass. The borosilicate glass/Duplex stainless steel construction provided four and a half times the pressure capability of the soda-lime/Hastelloy sight glass. The reliability of a sight glass has almost nothing to do with fused sight glass; compression is what matters most because it secures the glass to the metal and creates a leak-proof seal. Learn more about our full line of borosilicate sight glass products.

For all the details on this study, take a few minutes to read the white paper on compression vs. fusion.