Sight glasses (also called sight windows or viewports) are critical for visual inspection inside vessels, pipes, and tanks—but they also represent a potential safety vulnerability if mis-specified, improperly installed, or poorly maintained. There are a variety of critical safety tips and best practices to follow, based on LJ Star’s many years of selling METAGLAS®, the #1 sight glass in the world, along with working with processing facilities in some of the harshest environments.

To highlight these tips, LJ Star has published a new safety video that outlines these procedures to follow.

Process plant engineers consistently prioritize two critical goals when it comes to sight glass management: preventing unexpected downtime and minimizing safety risks from potential system failure. Sight glasses may seem like simple components; however, their failure can halt production for extended periods and create significant safety hazards.

While there are various options for sight glass materials, one type of sight glass, METAGLAS®, offers a unique advantage that is not well known—METAGLAS sight glass observation components are uniquely reusable. This feature not only extends service life but can also help reduce plant downtime while enhancing operational safety.

Fused sight glass is sometimes used to promote some brands of sight glasses based on the belief that greater fusion of glass to metal during the manufacturing process will produce a stronger finished sight glass for use in chemical and pharmaceutical processes.

We have recently learned that inferior gauge glass, with a historically common industry name, from an overseas supplier has entered the North American market and does not meet accepted standards of safety and performance.

We have recently learned that inferior gauge glass, with a historically common industry name, from an overseas supplier has entered the North American market and does not meet accepted standards of safety and performance.

While inherently resistant to corrosion, sight glasses can begin to corrode under the right circumstances, particularly if the wrong material is spec’d for the application. If a sight glass happens to corrode, it becomes increasingly vulnerable to sight glass failure. When glass fails, it is often sudden and catastrophic, damaging your system, putting workers at risk, and causing unplanned downtime. That’s why it’s important to understand the dangers of sight glass corrosion and failure so that you can adequately prepare for them… and avoid a costly disaster.

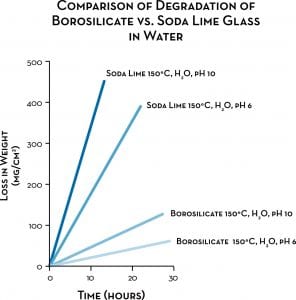

As hot water passes through ground coffee beans, it extracts flavors, colors, and stimulants that make mornings more livable for many of us. When it comes to pharmaceutical processing, however, extraction can be a bad thing, as leaching from process system surfaces can extract unwanted elemental impurities.

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

Not so fast. There is a wrong way to do anything, and choosing the wrong type of glass for a sight glass can have bad

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

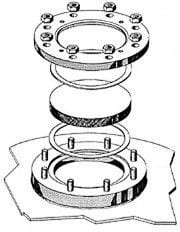

Sight glasses allow you to safely observe processes inside your tanks, vessels, pipes, and reactors. It is a window that allows operators to inspect the process media, observe reactions, observe the functioning of mixing equipment, verify the presence or absence of media, see liquid level, etc. It consists of metal, glass, and gasket components. In order to ensure optimal performance, a variety of factors need to be considered. Here are 5 critical things to consider when specifying a sight glass for your process.

“Learn the Secret of Sight Glass Strength” is a recent video from L.J. Star that outlines the precision process of fusing borosilicate glass to a stainless steel ring, then cooling it carefully to create a METAGLAS® sight glass window. Once the process is complete, the ring compresses the glass continuously, which gives it its exceptional tensile strength, preventing dangerous ruptures or fragmentation for greater reliability and safety. By combining the transparency of glass with the strength of steel, METAGLAS virtually eliminates the possibility of a sudden, unexpected rupture, and any crack that might develop, at worst, may slightly affect visibility. In addition to the unsurpassed pressure and impact resistance, the metal frame provides rigidity to prevent breakage if bolts are tightened unevenly during installation. METAGLAS products have been tested and approved by safety testing departments of several major chemical and other companies under a variety of conditions, most exceeding those normally encountered in practice.

For a process engineer, being smooth means more than knowing which wine to order in a fancy restaurant. In plant operations, the surface finish of a process vessel, piping, and related components can have profound effects on how well a fluid system performs. Surface roughness can affect fluid flow resistance (friction), adsorption/ desorption, bacteria growth, the build-up of chemicals from a process fluid, corrosion formation, pressure drop, etc. Ultimately, the smoothness of a surface finish can affect service life and maintenance costs. In a sight glass, for example, the surface roughness of both the glass and the metal mounting ring are critical for achieving a good seal in the installation.

An industrial sight glass is a critical part of virtually any type of process equipment because it allows for visual inspection of industrial and pharmaceutical processes. Luminaires are often used in conjunction with an industrial sight glass to illuminate tank and pipe interiors.

In a system made primarily of metal, like a pressure vessel, the weak spots are generally sealing joints and glass. However, an industrial sight glass is a highly engineered product. Although different brands of industrial sight glass might look alike, differences in their specs have tremendous impact on worker safety, sterile processes, and maintenance costs. In industrial applications, sight glasses are often subject to extremes of pressure, temperature, thermal shock, caustics, abrasion, or impact. Choosing the right industrial sight glass depends on taking all of these considerations into account.

Is your sight glass tough enough to handle “The Big Six” challenges?

Sight glass failures can be extremely dangerous. A sight glass that fails catastrophically has the potential for severe operator injury or death, as well as costly downtime and product losses. Even minor cracks, scratches or abrasions can create weakness within the sight glass, which will most likely lead to failure. In normal use, sight glasses are regularly subjected to forces involving extremes of pressure, temperature, thermal shock, caustics, abrasion, or impact.