What is a sight glass? Definitions for common sight glass terms.

A sight glass, which can also be referred to as a sight port window or a sight window, is an observation window that allows you to look at fluid stored under high temperatures, extreme pressures, and other extreme environmental conditions. They are typically made of robust glass substrates that are used to analyze conditions in industrial equipment, chemical reactors, and more.

Sight glasses are used in industries ranging from refineries to craft breweries. They allow you to look inside equipment without having to worry about explosions, corrosion, or other types of damage. Perhaps because of their widely-varied applications, sight glasses are called by different names. Broadly speaking, a sight glass is any kind of window on a process vessel or pipeline. However, there are other terms with more specific definitions. This blog post will explain them.

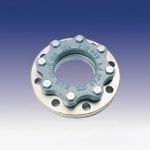

What does a sight glass look like?

A sight glass typically resembles a disc that is held between two metal frames, which is then bolted, fused, or clamped onto a frame.

The sight glass can be strengthened through a heat tempering process. The glass itself can also be coated to increase visibility and protect against certain chemicals and materials. With fused sight glasses, heat is applied to the glass disc and the steel ring that surrounds it. This causes the materials to fuse together, strengthening the glass by the compression of the metal ring.

This makes the glass resistant to tension and, overall, less likely to break and hurt employees.

Why should you use sight glasses?

Many equipment inspections require only simple visual observation. Because a sight glass does require you to open a closed system, it can save time and money, as well as preserve the quality of your resources.

A sight glass allows you to analyze the:

- Fluid quality (ex. color)

- Fluid levels

- Amount of contaminants

- Size of contaminants

- Type of contaminants

All of this can be looked at without having to open your system.

What should you consider when picking a sight glass?

Sight glasses are not a one size fits all. Therefore, it’s important to find one that suits your needs, in terms of durability and overall quality. Here are a few things to consider:

- Thermal Shock

- Corrosion

- Abrasion

- Pressure

- Impact

A sight glass can come in a variety of materials, but the window is typically made from thick borosilicate glass. This type of glass is very clear, with phenomenal light transmission and thermal properties. This glass works in conditions of up to 500°F.

Some manufacturers use soda lime glass, for less critical uses. This is typically for applications that require a temperature range of 300°F or less. But in situations where a stronger model is needed (temperatures over 500°F), it is best to use sapphire, steam, or quartz.

Types of sight glasses

Sight glasses come in two types: a conventional glass disc or a glass disc fused to a metal ring.

What is a sight glass assembly?

This is a glass disc that mounts between gaskets and then is secured by a retaining ring. This is the older style, traditional sight glass. Because the glass is exposed to mounting forces, it could have imperceptible cracks that could lead to failure. After the glass disc is removed from service, such as for cleaning, it should be replaced.

What is a sight glass window?

I think of a sight glass window (or “sight window”) as glass fused to a metal frame to create a single-piece component. This is the way to make the glass stronger, because the metal frame places the glass under compression. (Like cement, glass is weak under tension, but amazingly strong under compression.) The metal frame also takes the stress of mounting, making the glass immune to the forces of uneven bolting and gasket residue. Therefore, sight windows are re-usable.

What is a view port?

This is a term that distinguishes a sight glass used for viewing from a sight glass used for lighting. Often two sight glasses are installed on a tank: one on the top is dedicated to a light (called a “light port”) and one on the side is dedicated to viewing (a “view port”). As a cost-savings measure, some sight glasses are combined with a light at the same location. I have heard people call these “combos,” although I don’t know if that’s an official term.

What is a sight port?

It is not uncommon to encounter the term “sight port” used as a synonym for “view port” and even as a general term interchangeable with “sight glass.”

What is a sight flow indicator?

Pipelines are different from tanks and vessels in that the sight glass is used to observe flow. Commonly the sight flow indicator is an assembly consisting of two opposed sight glasses mounted to a housing. This arrangement allows ambient light to illuminate the flow from behind. There also versions using a tubular glass that admits more light and permits viewing from any angle. Another name for sight flow indicator is “visual flow indicator.” That’s my personal preference; the two names mean exactly the same thing.

What is a gauge glass?

Often tanks will have a vertical sight glass assembly used to observe the level of fluid inside the tank. Sometimes the glass has ridges in it that make it easier to see the line of fluid.

What is a boiler sight glass?

Boilers used in commercial and residential heating often have a tubular glass that makes it easy to observe water level. I’ve even seen this style of glass on an old-fashioned locomotive.

Lots of sight glasses, often made of plastic, are used in boats, lawn mowers, home brewing kits, etc. These are low-pressure, non-critical, low-cost components that are very different from the highly-engineered sight glasses used in industry.

That’s not to say that industrial sight glasses are not made of plastic. In many applications, such as the food and beverage industry, plastic sight glasses are widely used. The same definitions apply as above. Note that plastic sight glasses are never used with harsh media, high-pressure, or high-temperature processes.

What industries can sight glasses be used in?

Sight glass windows are used in the follow industries:

- Chemical

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Utility Industry

- Biogas

- Biofuels

- Biotech

- Oil

- Wastewater Treatment

Get more information about sight glasses and sight flow indicators from our guide: “Step-by-Step Guide to Sight Glass Selection.” Or, watch our video below on how to select the right sight glass.

Subscribe to our Blog

Categories

- Certifications

- Company

- In The News

- Industry Information

- METAGLAS® Sight Glasses

- PackExpo 2020

- Sanitary Clamps

- Sanitary Fittings

- Sight Flow Indicator Benefits

- Sight Glass Applications

- Sight Glass Construction

- Sight Glass Lighting

- Sight Glass Lights

- Sight Glass Process Vessel Camera

- Sight Glasses

- Trade Shows

- Webcast