Our process optimization equipment features:

- Smooth, crevice-free surfaces that eliminate dead legs or areas where bacteria can accumulate

- CIP/SIP compatibility for efficient cleaning between product runs

- Explosion-proof (EX) rated options for dust-prone environments

- Temperature-neutral LED lighting that won’t affect heat-sensitive formulations

- Wiper systems that maintain visibility in challenging processes

- Remote monitoring capabilities via advanced camera systems

Tailored Solutions for Specialized Processes

Extraction Processes:

- High-pressure monitoring for botanical extraction

- Temperature-sensitive operation monitoring

- Explosion-proof rated systems for safety

Powder Processing:

- Abrasion-resistant sight glasses

- Dust-safe lighting and monitoring systems

- Clear visibility for quality control

Mixing and Emulsion:

- Comprehensive process visualization

- Clean-in-place compatibility

- Custom material options for chemical compatibility

Remote monitoring capabilities are particularly valuable in explosion-proof environments, allowing operators to maintain consistent oversight while minimizing disruption to sensitive processes. Our camera systems can be accessed through mobile devices, enabling production supervisors to monitor operations across multiple shifts efficiently.

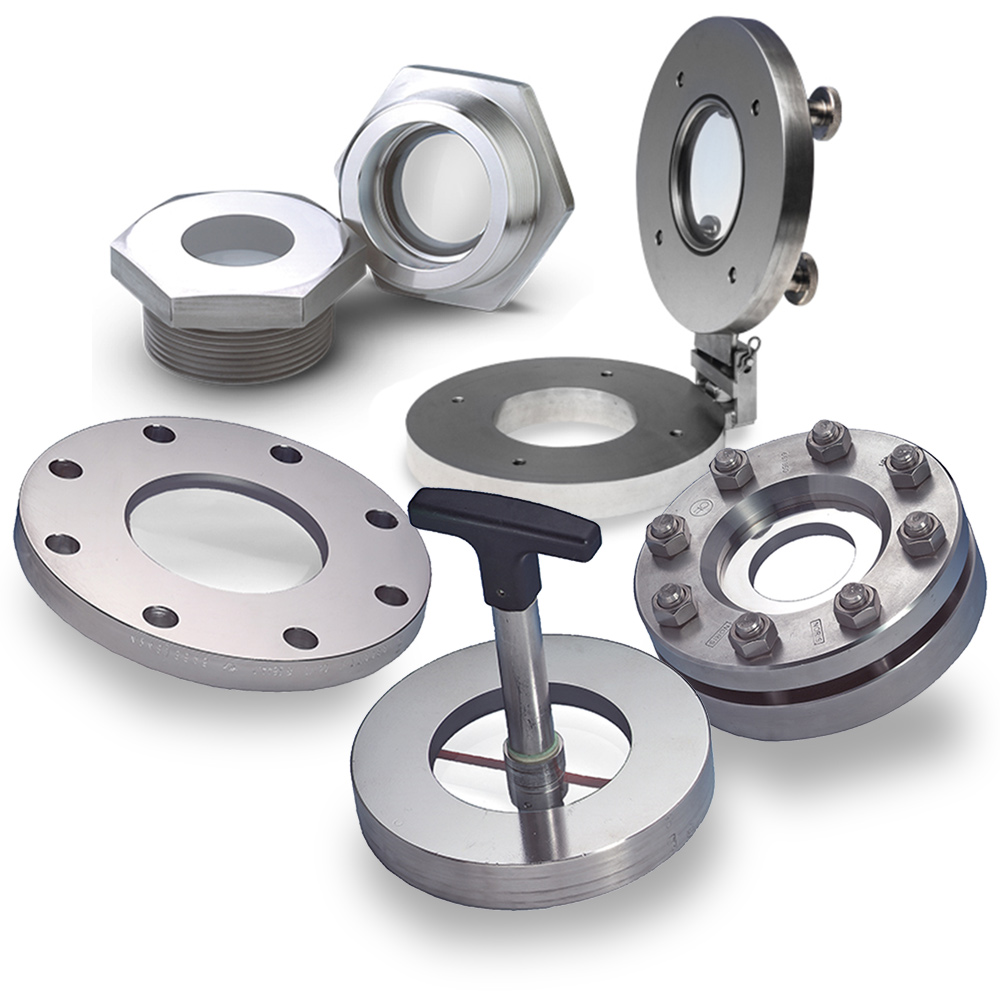

Full Suite of Sanitary Accessories

Sanitary clamps seal ferrules without crevices that could harbor bacteria, to facilitate cleaning vessels and connections between batches. Botanical extraction for example, depending on the method used, can involve significant temperature variations. LJ Star sanitary fittings are manufactured with the highest quality materials built to withstand high pressure and thermal cycling that can stress valves and fittings.

For example, a high-pressure hygienic connection with the ASME Section VIII-rated Sanitary Clamp offers the greatest protection and ensures uniform clamping compression. This Sanitary Clamp is cast from 316 stainless steel and features a heavy-duty three-bolt and hinge design that enables quick cleaning and allows inspection access without compromising safety.

LJ Star also carries LED lighting which, when paired with a sanitary sight glass or viewing ports, provides clear illumination of process conditions while consuming minimal energy and generating negligible heat. The cool nature of LED lighting helps maintain temperature control during sensitive processes, while offering a long lifespan to reduce maintenance needs.

Quality Assurance and Documentation

Our comprehensive documentation packages support full material traceability requirements. Equipment is available with complete certification documentation to meet regulatory compliance needs.

Our staff is well versed in selecting materials optimized for specific chemical compatibility requirements, ensuring long-term reliability and maintaining product integrity throughout your manufacturing process.

Contact our technical team to discuss your specific cosmetics or nutraceuticals manufacturing requirements and discover how our process optimization solutions can enhance your operations.

Products

Watch our Video

Solutions for Cosmetics and Nutraceuticals Industries

Enhance regulatory compliance, quality control and operational excellence in pharmaceutical manufacturing with a tailored process observation solution from LJ Star. Contact us today to realize greater visibility, improve product quality, and reduce waste.

Speak with the industry experts at LJ Star today, so you can see a better tomorrow.