What’s The Best Type of Lighting For My Sight Glass?

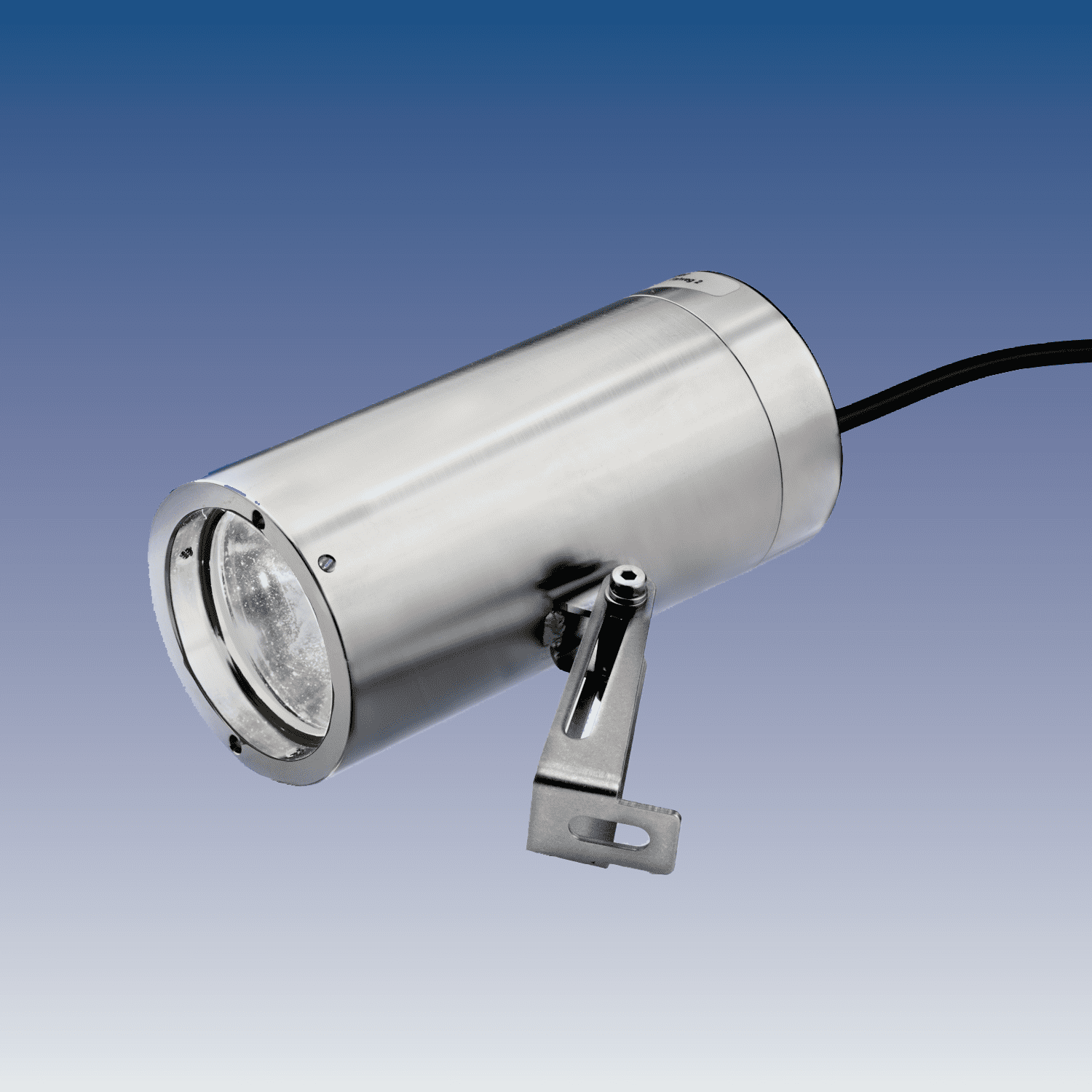

Posted on December 20, 2019 by LJ Star Mounting lights, or “luminaires”, are required in most sight glass applications in order for operators to be able to accurately see what’s going on inside a vessel or pipeline. Where flashlights and other commercial lighting solutions fail, industry-grade mounted lights can provide direct, high-powered illumination that can light up even the darkest environments.

Mounting lights, or “luminaires”, are required in most sight glass applications in order for operators to be able to accurately see what’s going on inside a vessel or pipeline. Where flashlights and other commercial lighting solutions fail, industry-grade mounted lights can provide direct, high-powered illumination that can light up even the darkest environments.

Get The Most Out of Your Sight Glass

In order to get the most out of your sight glass, L.J. Star recommends choosing the right type of lighting for your application. There are several types of lighting technologies that you can pick from. The 5 main types of mounting lights that engineers use are:

- Halogen and Incandescent Lights

- LED lights

- Metal Halide (HID) Lights

- Fiber Optic Lights

- Compact Fluorescent Lights

Of these options, halogen lights have typically been the most common type of light used in sight glass applications. A lot of this has to do with initial cost. Halogen lights are among the least expensive lights that you can get, while still having enough power behind them to properly light your sight glass. Due to their low cost, these lights have been easily adopted for sight glass applications and are readily available for engineers to implement in their designs.

Drawbacks to Halogen Lights

However, despite their popularity, there are some drawbacks to halogen lights that you need to be aware of. These include:

- Low efficiencies due to 85% of energy consumed by heat generation

- Low color temperatures can cause eye fatigue after extended use

- Limited bulb life due to easily damaged filaments

- Frequent maintenance/replacement required

- Technology is being phased out

In many cases, these drawbacks will not significantly impact your operations, making halogen lights still a good choice for many basic applications, while supplies last. That said, for engineers that find the above to be troublesome or desire more out of their lights, there are many other options that don’t have the same drawbacks.

That’s why many engineers are increasingly choosing other lighting solutions over halogen lights to illuminate their sight glasses. LEDs especially are growing in popularity. Their longer service life and more rugged design make them better choices for any applications involving harsh environments, in which mounting lights are frequently used. Other features that come with LED lights include:

- Smaller sizes when compared to halogen lights at an equal brightness

- Cold light output

- High efficiencies due to low operating costs

- Directional light

- Easy-to-control color output leading to greater definition and less eye fatigue

- Unwanted radiation removal, such as ultraviolet and infra-red light

LED Lights for Sight Glass Lighting

LEDs offer clear advantages over halogen lights, but sometimes you’ll want a lighting solution that was specifically made for applications that require long continuous use and a high intensity output. HID lights are a good choice in these situations. These types of lights also offer:

- Cool burning

- Lower power consumption

- More light produced at a higher color temperature

When thinking of choosing a HID lighting solution, it should be noted that these lights require a ballast. This controls the starting and operating voltages of the lights and limit the flow of current through them, ensuring optimal operating conditions.

If your application limits your mounting options, such as with tight spaces, fiber optic process lights will be your best option. They can offer a high degree of flexibility that other types of lights can’t. With this flexibility, you can illuminate hard to reach areas or remove the light source from vibrating work surfaces that could damage the bulb. Designed to uphold and maintain a cold light output, fiber optics can be used with either halogen bulbs or LEDs.

Florescent Lights (CFL) for Sight Glass Lighting

One other option that can come up when thinking about sight glass lighting is to use compact florescent lights (CFL). Most commonly used for lighting residential areas, these lights last a long time (upwards of 10,000 hours per bulb) and require only 20-25% of the energy cost of halogen lights. However, CFLs aren’t great for sight glass lighting due to their inherent difficulty reflecting light. Other disadvantages include:

- Cold temperature sensitivity

- Required mercury disposal

- Limited color temperatures

- Longer warm up times

No matter what type of lighting you choose for your sight glass, it is imperative you go with an explosion-proof design if your environment or application is prone to an explosion-causing spark. L.J. Star offers a wide range of explosion-proof lights in a variety of sizes and types, from traditional halogen bulbs to LEDs and fiber optics. All designs meet either UL or ATEX requirements for their respective types of hazardous environments.

If you want to learn more about your lighting options, click here to take a look at our lighting handbook.

Subscribe to our Blog

Categories

- Certifications

- Company

- In The News

- Industry Information

- METAGLAS® Sight Glasses

- PackExpo 2020

- Sanitary Clamps

- Sanitary Fittings

- Sight Flow Indicator Benefits

- Sight Glass Applications

- Sight Glass Construction

- Sight Glass Lighting

- Sight Glass Lights

- Sight Glass Process Vessel Camera

- Sight Glasses

- Trade Shows

- Webcast