A sight flow indicator gauges the direction and speed and flow of the process material. It is a product installed in a pipe that provides a visual aid to verify liquid flow for direction and accuracy.

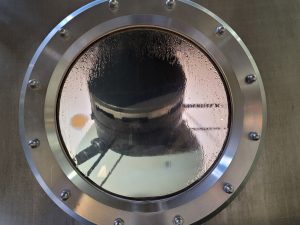

Sight flow indicators never go out of style, but they do require occasional replacement, either as part of the facility’s overall maintenance plan or to repair damaged units. When installed in process pipelines, sight flow indicators allow visual observation of the direction and rate of flow of liquid, powder, or gas process media, as well as the media’s color and clarity, through one or more observation windows.

Before you contact a sight flow indicator vendor to place an order, take a few minutes to answer the following questions. Having this information readily available will not only speed the specification process but will help ensure you get the most appropriate product for the application.

Types of Sight Flow Indicators You May Utilize

Types fo sight flow indicators include,

- 360° view flow indicator (sometimes called a full view, cylindrical, or tube-style flow indicator) passes the process media through a glass cylinder that is visible from all angles, which allows ample ambient light to illuminate the flow. It is ideal for observing process fluids for clarity, color, foam, and other conditions, and for the presence of moisture. It is not appropriate for high temperatures or high pressures.

- A view-through flow indicator has two opposing windows that allow the operator to see the intervening flow of fluid as lighted from behind, either by ambient light or with an attached luminaire. This design is suited for ANSI pressure classes, high temperatures, and harsh fluid applications.

Sight Flow Indicator Flapper Type

Sight Flow Indicator Flapper Types include,

- hinged flapper- Flow indicators may be fitted with a hinged flapper or flag visible through the glass. The flapper is deflected toward the direction of flow. Because the position of the flapper changes in relation to the force of flow, it offers the operator an approximate gauge of flow.

- A rotary flow indicator is fitted with rotors or impellers that are turned by the flow of liquid or gas. The rotors are mounted in the window view so operators can observe the direction and approximate speed of flow. This is particularly useful for clear gases and fluids, but the rotor is visible with dark fluids as well.

- Drip indicators may be models designed for drip observation or conventional flow indicators installed with a drip tube. These types of flow indicators are suitable for observing drips and low-volume intermittent flows in applications such as distillation. Because they depend on gravity, drip indicators are normally used in vertical pipes with a downward flow.

What are the sight flow indicator mounting types?

Sight flow indicators are available with three basic mounting options

- Flanged

- Threaded

- Sanitary clamp

Flanged indicators have pre-drilled bolt holes. Be sure to let the supplier know the size of the flange to which the sight flow indicator will be connected so that the bolt holes line up with each other. The pharmaceutical industry uses clamp-on indicator mountings so that all components can be easily disassembled for cleaning.

What is the connection size of a sight flow indicator?

Sizes depend on the manufacturer but generally, the connection size of a sight flow indicator ranges from ¼-inch to 16 inches in diameter, with larger units available as special orders. Provide this measurement to the supplier specified in either inches or millimeters.

What materials are a sight flow indicator made of?

When specifying the type of materials a sight flow indicator should be made of, keep the compatibility of the various components in mind. Carbon steel and stainless steel are the two most common materials used for the body. Stainless steel offers better corrosion resistance and is widely used in pharmaceutical applications. Gasket integrity is crucial to successful indicator performance so ensure that the gasket material used is compatible with the process media with which it will come in contact. Standard gaskets for most industrial applications are made of an enhanced PF material or Teflon.

Which type of window glass does the application demand?

Glass can come as a conventional glass disc or as a glass disc fused to a metal ring during manufacturing. Fused windows hold the glass in concentric compression that makes the glass resistant to bending stresses that would otherwise cause cracks or failure.

They are used when high-pressure ratings, impact resistance, and safety margins are needed. Such fused glass windows are popular in the chemical, pharmaceutical, and food industries. Standard soda glass windows can be used when temperatures are less than 300°F and when there are no corrosive materials and no drastic temperature fluctuations (which could lead to thermal shock).

Both conventional soda-lime and borosilicate glass discs should be replaced and not be reused after maintenance (disassembly), because tiny fractures may occur during mounting that is not visible to the naked eye. In some conditions, soda-lime glass can leach into the process media. For temperatures of 300–500°F, borosilicate glass is typically used because of its higher resistance to thermal shock. Borosilicate glass should be specified in areas where hot equipment may be washed down with cool water, even for temperatures of less than 300°F.

In applications involving contact with caustic or acidic chemicals, borosilicate glass is less likely to experience clouding and erosion than soda-lime glass. If the glass is fused to its metal frame, then reuse is no problem, because the metal ring takes the stress of mounting. Quartz or sapphire glass is recommended for temperatures greater than 500°F, such as in high-temperature steam applications.

What levels of temperature and pressure must the flow indicator withstand?

The allowable pressure/temperature limitations for a sight flow indicator depend on the durability of the materials used in its body, retainer, window, and gasket. When talking with the vendor, always clearly specify the levels of temperature and pressure the sight flow indicator must be capable of enduring.

How to Choose the Right Sight Flow Indicator

For more tips on how to identify the right sight flow indicator for specific applications, download our free copy of L.J. Star’s Sight Flow Indicators Handbook.

L.J. Star is a trusted sight flow indicator manufacturer. Contact us today so we can assist you with your sight glass needs.