5 Things to Consider When Picking a Sight Glass

Posted on June 13, 2016 by LJ Star I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

Sight glasses allow you to safely observe processes inside your tanks, vessels, pipes, and reactors. It is a window that allows operators to inspect the process media, observe reactions, observe the functioning of mixing equipment, verify the presence or absence of media, see liquid level, etc. It consists of metal, glass, and gasket components. In order to ensure optimal performance, a variety of factors need to be considered. Here are 5 critical things to consider when specifying a sight glass for your process.

Let’s get started.

1. PRESSURE

The glass materials selected, the unsupported diameter, and the glass thickness all play a role in determining the pressure capabilities of a sight glass assembly.

There are two types of sight glasses: a conventional glass disc and a glass disc fused to a metal ring during manufacturing. The metal ring squeezes the glass and holds it in radial compression. Glass typically fails as a result of being subjected to significant tension. With fused sight glass windows, the compressive force of the metal ring exceeds the tensional force (i.e., pressure) and, as a result, the sight glass is extremely resistant to failure. Fused sight glass windows offer high-pressure ratings and high safety margins.

The strongest fused sight glasses are made from duplex stainless steel and borosilicate glass; this combination creates the highest compression.

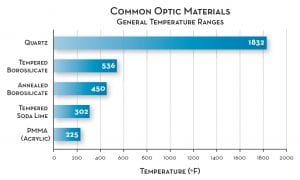

2. TEMPERATURE

The temperature will determine the glass type and more commonly the gasket material.

Download our Chemical & Pharmaceutical Sight Glass Application Handbook

3. MATERIAL OF CONSTRUCTION

Carbon steel and stainless steel are the two most common metals used. Stainless steel offers better corrosion resistance and is standard in pharmaceutical applications.

4. METHOD OF CONNECTION

There are three methods to connection:

- Weld-on. If the sight glass will be welded on, consider the following:

- What will be the temperature and pressure inside the vessel? Sight glasses are rated for maximum temperature and pressure.

- If the sight glass is going to be welded into place, the vessel onto which it will be welded likely hasn’t been created yet. The size of the hole for the sight glass should be specified before the vessel is made.

- Is the tank ASME? If so be sure to only use ASME wetted parts.

- Bolt-on. When your sight glass is mounted to an existing flange, bear in mind the following:

- Bolt-on sight glasses come with existing bolt holes. Be sure to let the sight glass supplier know the size of the flange to which the sight glass will be connected so that the bolt holes match up.

- There are pressure limitations depending on the type of flange used. Bolt-on sight glasses are generally specified as 1) good to 15 lbs. psi or 2) for anything over 15 lbs. psi. Sizes should follow ANSI specification guidelines and materials should follow ASME standards.

- Clamp-on. The pharmaceutical industry uses clamp-on sight glasses so that all components can be easily disassembled for cleaning.

5. PRODUCT CONTACT CONCERNS

Will the sight glass come into contact with corrosive process media? Will it be subject to sanitize in place/clean in place processes? Will it be exposed to thermal cycles or extreme heat? Your L.J. Star expert can guide you to the specific glass, gaskets, linings, and shields that you will need.

Now that we have walked through the process and took a deeper look at what needs to be considered in choosing your sight glass if you still have questions our sales team is happy to assist you so you can begin to see more clearly.

How to Select the Right Sight Glass

For more information about sight glass applications, download the Sight Glass Handbook for Chemical and Pharmaceutical Applications

Subscribe to our Blog

Categories

- Certifications

- Company

- In The News

- Industry Information

- METAGLAS® Sight Glasses

- PackExpo 2020

- Sanitary Clamps

- Sanitary Fittings

- Sight Flow Indicator Benefits

- Sight Glass Applications

- Sight Glass Construction

- Sight Glass Lighting

- Sight Glass Lights

- Sight Glass Process Vessel Camera

- Sight Glasses

- Trade Shows

- Webcast